Why us?

Mission

We would like to introduce anyone willing to improve to enter a less complicated, but highly efficient world using technical ceramic products. It’s out of the mainstream, but often allows a better solution to tricky situations than conventional metal industry products.

If it’s simple, it imposes less of a burden to our engineers, economy, and our planet as well. We work for that – a more friendly and cleaner world.

We believe in long-term partnerships measured in decades.

Professional Know-how

MIKERON produces industrial ceramic parts for more than 30 years. Our parts are used by hundreds of satisfied customers around the world from mining and metallurgy to high-tech medical devices or semiconductors production.

Our ceramic material is harmless and inert, products are manufactured and operated without using of dangerous or environmentally destructive substances or by-products. We believe in the positive returns lowering our partner’s carbon footprint and easing waste management.

Unique technology

Usually we work with wet isostatic pressing and precision CNC machining. This allows us to maintain geometrical and material properties to meet difficult demands even from prototype-sized series to regular quantities.

Continous improvement

Research and development are essential to keep up with the changes in our industry. We participate in various R&D projects with universities and research facilities. Numerous PhD theses and other papers have been publicated thanks to our special student program.

We are always partners in research if you want to improve your production or get a whole new idea to try.

About us

MIKERON was founded in 1989 and remains a fully Hungarian owned company ever since. Our company philosophy paved the way in establishing our business: we prefer precision and added value over quantites and regular ceramic mass products. We would like to introduce people to a world where we can solve hard problems thinking differently, providing an easy, relatively cheap and reliable solutions. We support research and development and want to make people move freely in the ceramic world, so consultation and production planning usually comes with no charges.

In the first few years we focused mainly on chemical industry, producing ceramic pump parts, valve balls, various nozzles and pistons. As demand appeared, higher added-value precision parts became standard mainly supplying medical industry (mainly ceramic shear valves, then automotive and several other fields of application. Later it became clear that a simple product is not sustainable by itself (and sometimes tedious and expensive to handle customer needs), so we implemented our joint project service. We know that even large businesses start with small steps, and wish to provide lots of help in this phase – how they work, how to design them, how to use them correctly. Instead of maximizing profit, we believe in working and gaining together.

Our workshop became more and more versatile: specially modified CNC machining centers took over the job of conventional machines. These allowed us to catch up with the latest trends and fabricate top-notch quality products. Our expert team manages to adapt to new tasks and circumstances, working wholeheartedly to give the best solutions possible.

According to technical documentation, 3d model or some kind of joint development, we can handle orders even with rather strict tolerances, in small or larger quantites as well.

Al2O3 ceramics info

“If your plastic/metal part or component wears, burns, warps, got “eaten away” or has suboptimal performance, just contact us – we will work on it”

Al2O3 ceramics are a real problem solver outside the labyrinth of heat resistant steel – abrasion resistant coating – acidproof steel triangle. It’s hardness is diamond-like, it won’t warp when exposed to heat (working temp max. 1400°C), has low thermal expansion. Acids or bases do not affect its performance (see datasheet for exceptions), its chemical resistance is exceptional. It can be machined fairly well, for example to the complexness of an engine piston and beyond. Our material has its own drawbacks as well as relatively low heat-shock tolerance or its stiff (brittle) compositon, but with proper design and know-how these can be kept at bay. If you are unsure, contact us for our advice. We can find a solution.

Al2O3 ceramics have many other advantages like superb electric insulation, wear resistance or easy sterlilization (no open porosity).

Our company uses 4 materials in the majority of cases:

95%, 96% purity ceramics, common applications

Reasonable price and good machinability allows us to produce a great array of parts reaching high quality. Their physical properties are almost the same, the 96% alumina comes with a much brighter white color, and it is much easier to machine (difficult shapes, thin walls). On the other hand, part precisity is a bit lower than than the 95% variant.

Application examples: ceramic welding pins, wear parts, nozzles, valve balls, machine parts, sliding bearings etc.

99,7%, 99,8% purity for extreme applications

These materials excel in the extremes. No atomic contamination is detectable even at 600 degrees Celsius, so these are able to perform well even in semiconductors processing. Medical industry and presision measuring equipment show the greatest demand towards them. We recommend those materials to produce high purity ceramic actuators, medical shear valves, or measuring equipment parts.

Their physical properties show minor differences: the 99,8% alumina is much harder to machine, but can reach higher density (chemical resistance etc).

However higher purity means expensive raw materials and difficulty in machining and processing in general, which means those products represent a higher price level.

Industries

Our products are used in more than 50 fields of application.

Our products

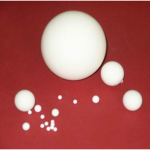

Usually we manufacture parts directly designed to be made of alumina ceramics, but we gladly replace your old steatite or porcelain parts too, using our materials. You can find ceramic medical shear valves, high precision valve balls (size d10-d200), valve seats, special crucibles, pistons, welding pins etc.

We supply our automotive partners with wear resistant ceramic connector masks, ceramic welding pins, various production line elements and measuring equipment parts. There is a significant demand for counseling, whether the matter is to design something new or replace an “old” part or process.

If we know the working conditions in depth, we are happy to work on your problem and offer you a solution.

We are able to lap our products to reach 0,0004mm flatness, polish them to Ra0,1 or fine grind to diameter tolerance of 0,01mm.

You can find several other products in the following gallery.

Services

Besides following technical documentation, we can offfer some other services as well:

Joint product development from the designing table to manufacturing

Supporting maintenance through redesigning and replacing problematic non-ceramic parts

Optimisation: improving existing documentation of ceramic parts to reach a better result financially or in performance

Consultancy in material selection and manufacturing principles: if we know your problems (wear, expensive maintenance etc.) we can design the best solution

Ceramic insert production to upgrade existing metallic, plastic or other parts

References

We can boast hundreds of satisfied partners: